Breakthrough Innovations for Sustainability

OVERVIEW

Our aim is to strengthen our man-to-land ratio and estate productivity to increase yields.

The world’s growing population is expected to reach almost 10 billion people by 2050, which means global demand for commodities such as vegetable oils will continue to rise sharply7. A responsible approach to meeting these needs is ensuring increased palm oil production does not lead to further deforestation or environmental degradation.

That is why SDP’s Research and Development (R&D) teams are working to find new ways to increase yields and produce higher volumes from the same amount of land. One of our innovations supporting increased yields is precision agriculture, which uses advanced geospatial technology to tag palms and keep track of their location. By taking regular images of the same palms, we can measure growth rates and forecast yields, monitor palm health, understand the effectiveness of our water distribution, and detect the presence of diseases. We are also scaling up automation at our plantations to further improve production and yields. Our aim is to strengthen our man-to-land ratio and estate productivity to increase yields and overall throughput whilst progressively reducing our dependence on manual labour.

7Population Reference Bureau, 2021 World Population Datasheet. Available at: https://interactives.prb.org/2021-wpds/

Leading the way with high yielding seeds

[GRI 3-3]

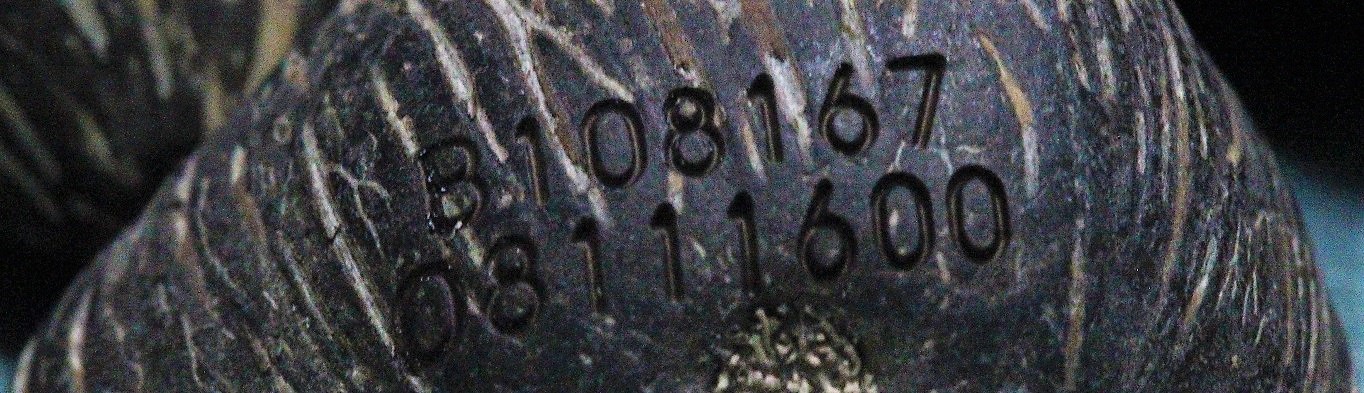

We currently yield an average of 4–5 tonnes of oil per hectare (MT oil/ha) across all our plantations. Since 2009, we have intensified our efforts to boost yields with better oil palm seeds and introduced our elite variety, Calix 600™. Since 2008, SDP has invested MYR150 million to support our world-class R&D teams in developing our latest and best planting material, GenomeSelect™ seeds. GenomeSelect™ can deliver oil yield improvements of up to 15% above our Calix 600 ® seeds, with an average of 6.1 MT/ha across all environments, and yield potential above 10 MT/ha in the most fertile environments. This development will enable the Group to increase our yield by the equivalent of 50,000 hectares of new land without increasing our planted hectarage. Through our replanting programme, we expect to lower the average age of palms at our plantations from approximately 13 years in 2017 to about 12 years.

Calix600 ® has been phased out, with the last round of planting carried out in 2022. GenomeSelect™ is now being planted commercially at our Malaysian operations and all replanting moving forward will use GenomeSelect™. As of December 2021, we have replanted over 3,800 hectares across Malaysia with GenomeSelect™. In terms of production, we are on track to meet 100% of our replanting needs in Malaysia by 2023. In 2021, a total of 1.47 million GenomeSelect™ seeds were produced, and we expect to double production by the end of 2022.

At the time of this report’s publication, GenomeSelect™ is currently being rolled out at our other operations. In Indonesia, planting of mother palms has begun, and these are expected to produce local GenomeSelect™ seeds by 2024. At our operations in PNG and Solomon Islands, NBPOL manages their own high-yield material called SuperFamily® seeds. A product of the world-renowned Dami Research Centre, the SuperFamily® seeds programme takes the best 0.1% of planting material from mother palms and crosses it with the best pollen from pisifera palms to produce a super seed. GenomeSelect™ will build off the current best planting material to further boost current yields. We are currently producing new GenomeSelect™ mother palms for future seed production, which will start producing seeds locally in 2027.

To support other interested stakeholders looking to improve yields and minimise land expansion, SDP has made our research on the oil palm genome available through open-source online journals. Other industry players and sector stakeholders can access and import this genetic information to fast track their own yield improvements. We are also preparing to make GenomeSelect™ seeds commercially available to third parties by 2023.

GenomeSelect™ is a milestone achievement and the cornerstone of SDP’s future. Our R&D teams will continue to improve it over the coming years. We aim to double our commercial yield average to 8 MT oil/ha by 2050 in applications across all environments and expect our yield to climb above 11 MT oil/ha in optimal conditions.

Building resilience to climate change impacts

Unlike genetically-modified crops, GenomeSelect™ oil palm seeds are naturally pollinated seeds that have been genetically tested and selected. Thanks to new digital systems and geotagging technology, we can collect genetic data about planted GenomeSelect™ seeds. This information will help us understand how these palms respond to drought, salinity and seasonal changes to improve their resilience to climate change impacts. In addition, these palms will be more resistant to diseases such as Ganoderma. In the coming years, we hope to further increase the high-yield of GenomeSelect™ through research into other oil palm traits that can speed up harvesting and increase tolerance to climate change impacts.

Automation and Mechanisation at Plantations

[GRI 3-3]Palm oil production is a labour-intensive industry and is highly dependent on skilled harvesters. In Malaysia, the industry has relied on foreign workers for many years to fulfil demand. However, there is a local and regional shortage of workers due to several factors. As the country continues to develop better urban employment opportunities, workers are less willing to accept jobs considered ‘dirty, dangerous and difficult’ (3D). COVID-19 travel restrictions have further complicated the situation, and closed borders have created an acute labour shortage at plantations.

Whilst it has been our long-term vision, recent events have made it even more imperative to find innovative ways to reduce SDP’s dependence on manual labour. Since October 2020, we have invested heavily in Project Infinity, a cross-collaborative, inter-departmental R&D initiative exploring ways to automate our labour-intensive harvesting processes. SDP has examined innovative options in automation, digitalisation, and robotics. Using a multi-pronged approach and automating repetitive tasks, our ultimate goal is to attract local workers with greater skill levels to operate these new processes.

Below is our strategy to increase our man-to-land ratio from the current 1:14.8 to 1:17.5 by 2025 and plans to transition to a highly-skilled local workforce. Through this strategy we envision increased opportunities for different skills, enhanced mitigation of safety and health risks, and the creation of various subsectors to support automation initiatives.

Strategy to Realise Project Infinity

ACCELERATION THROUGH MECHANISATION

-

Using drones for pest and disease control and point-to-point spraying for pest breakouts

As of December 2021, we have engaged local drone start-ups for pest and disease spraying at nurseries and immature areas. In doing so, we have reduced labour by up to 87% for nursery spraying and up to 69% for point-to-point spraying in immature areas. This has also reduced the cost of point-to-point rhinoceros beetle spraying using the Selarong Eagle Sprayer.

-

Fertiliser application through machines

We will be rolling out two initiatives – the Mechanical Fertiliser Machine and the Mechanical Terrace Fertiliser Application – that are expected to eliminate up to 81% of labour and 45% of the fertiliser application cost. We are also introducing an automatic circle and strip sprayer, the ST 101 GEO, that is expected to eliminate up to 79% of labour and 33% of spraying cost. An Immature Herbicide Sprayer for circle spraying at immature areas is also currently being prototyped.

Objective

To increase the man-to-land ratio from the current 1:14.8 to 1:17.5 by 2025. This means each person in the field will be able to manage more land through automation, requiring less labour and fewer but better-trained workers

LEAP (BREAKTHROUGH INNOVATION)

- Establish an internal robotics team to leverage advancements in robotics and develop in-house solutions, taking automation to the next level

- Invest in R&D to improve yields and extraction rates through our GenomeSelect™

-

Reimagine the industry’s approach to upstream operations by:

Objective

By transitioning from manual to mechanised and automated methods, we can potentially reduce labour requirements by an additional 5% for:

ULTIMATE GOAL: PROJECT LOKAL

Objective

Our ultimate goal is to attract a highly-skilled local workforce to manage modern, mechanised and automated plantation operations. We will create desirable technical jobs and careers for specialists, including those with tertiary education qualifications in specialised fields such as computer science, robotics, and software and hardware engineering.